Introduction

In today’s increasingly digital and networked world, the security and efficiency of data transmission have become central to technological advancement. Since its introduction in 1996, USB (Universal Serial Bus) technology has undergone several upgrades, with USB 3 technology standing out for its exceptional high-speed transfer rates and performance. Optical electrical isolation technology, as a crucial tool for enhancing the security of data transmission, brings new development opportunities to USB technology. This article delves into the development and challenges of USB 3 optical electrical isolation technology, using the custom development case of Smartavlink with medical device manufacturers as an example to demonstrate this technology’s key role in connecting and shaping the future.

USB 3 Optical Electrical Isolation Technology Overview

USB 3 technology, also known as SuperSpeed USB, offers transfer rates of up to 5Gbps, far exceeding its predecessor USB 2.0 in performance. This breakthrough means faster data transfer speeds, higher energy efficiency, and optimized bandwidth utilization. Simultaneously, optical electrical isolation technology uses light signals instead of electrical signals for data transmission, achieving physical separation between parts of an electrical system. This isolation not only prevents electrical interference and ground loop noise but also significantly enhances the overall system’s electrical safety, especially in high-risk environments such as medical equipment and industrial control systems.

Custom Development Case of Smartavlink with Medical Device Manufacturers

The collaboration case of Smartavlink with medical device manufacturers highlights the importance of USB 3 optical electrical isolation technology. Ensuring the safety of data transmission while enhancing the performance of their medical devices was a challenging task for the manufacturers. To address this need, Smartavlink custom-developed an efficient USB 3 optical isolation solution for their medical device clients, satisfying the 5Gbps transmission requirement and conforming to strict medical safety standards. This collaboration showcased Smartavlink’s expertise and innovation in the field of optical electrical isolation technology.

Technical Points and Specifications In the development of the USB 3 opto-electrical isolation module, the technical requirements were strict and detailed. These included support for high-speed data transmission rates of up to 5Gbps, maintaining compatibility with USB 2.0, and complying with medical device safety standards like IEC 60601-1. Additionally, the physical size of the module was crucial, particularly in space-constrained applications. Smartavlink excelled in these areas, successfully overcoming the technical challenges faced by medical device manufacturers.

Case study: Medical Oral Scanner Connectivity Solution

Imagine a scenario in a dental clinic where you are waiting for your appointment. The dentist enters the room, holding a compact medical oral scanner, ready to examine your teeth. This scanner does not operate independently; it needs to connect to the dentist’s laptop to view and record oral images in real time. This is where the USB 3.0 optical module from medical device manufacturers comes into play. The USB 3.0 optical module is an innovative connectivity solution provided by SmartAVLink, aiming to simplify and enhance the connection between medical oral scanning devices and laptops while ensuring compliance with medical regulations and safety standards.

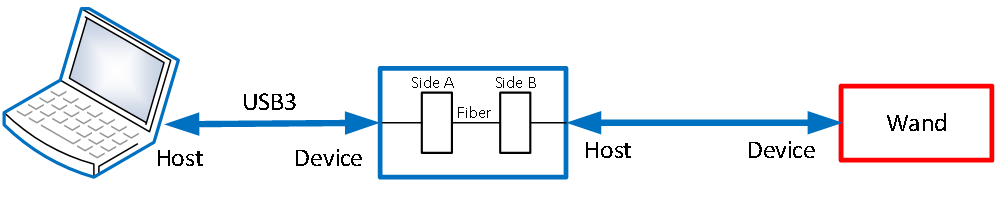

Purpose and Application of the Optical Module The primary purpose of the medical device manufacturers’ USB 3.0 optical module is to connect specific medical intraoral scanners to commercial laptops. This connection process is not straightforward, as it must meet stringent medical regulations, particularly the IEC 60601-1 standard. The USB 3.0 optical module must also provide electrical isolation to ensure a safe electrical connection between medical devices and computers.

SmartAVLink as the Solution Provider SmartAVLink, a company focused on providing high-quality connectivity solutions, collaborated with medical device manufacturers to develop the USB 3.0 optical module to meet the strict requirements of the medical industry. Below are the two solutions provided by SmartAVLink that successfully developed the USB 3.0 optical modules for medical device manufacturers.

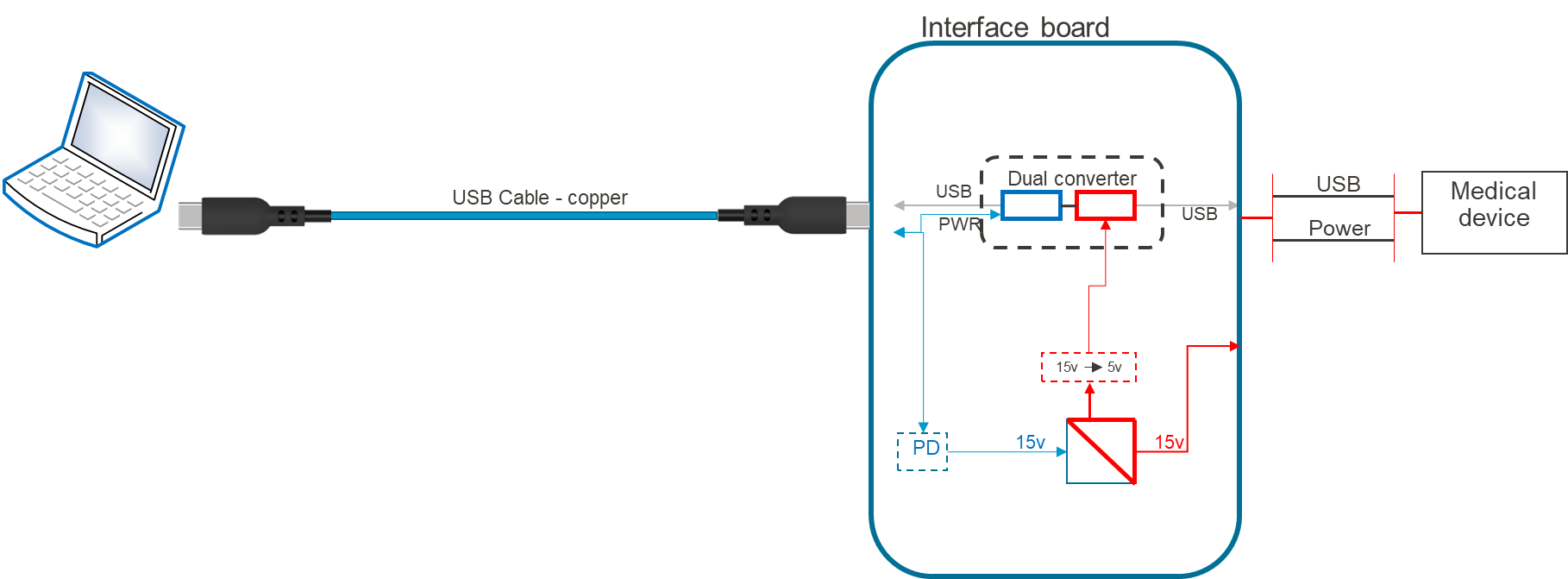

- Embedded Optical Converter Module: This solution embeds the optical converter module into the connection interface board, making the module more compact and portable. The optical converter module achieves high-speed USB 3.0 data transmission while providing electrical isolation, ensuring a safe connection between medical devices and computers. This solution complies with the IEC 60601-1 standard and other medical regulations and has undergone rigorous electrical safety testing and reliability verification.

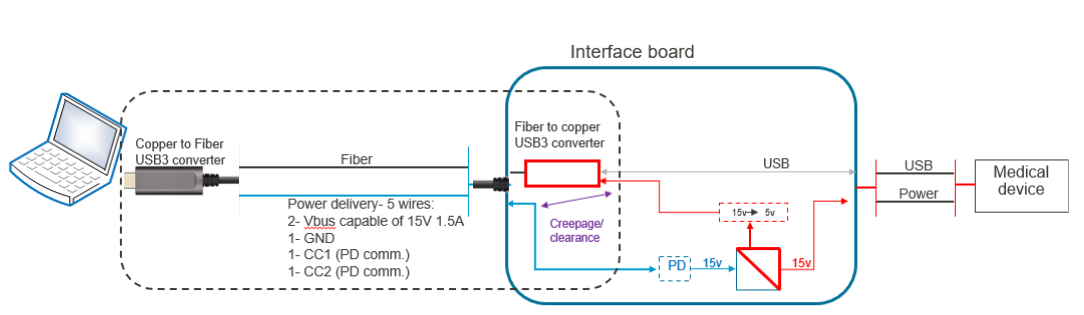

- Hybrid (Fiber Optic + Copper) Cable: Another solution uses a hybrid cable that includes both fiber optic and copper wires. This option is more suitable when longer cable lengths or greater flexibility are required. The fiber optic part ensures high-speed data transmission, while the isolated copper wire provides power supply. This solution also meets the IEC 60601-1 standard and other medical regulations and has undergone electrical safety testing and reliability verification.

Functional Requirements

The USB 3.0 optical module must meet various functional requirements to ensure effective connectivity and operations:

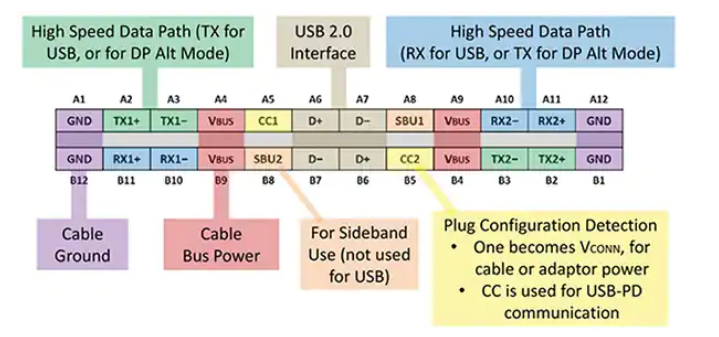

Supports isolated USB 3.x SuperSpeed transmission with data transfer speeds of up to 5Gbps, while being compatible with USB 2.0 interfaces.

Power transmission line (applicable only to option 2): Provides isolated copper wire, capable of supplying power up to 15V 1.5A to the scanner.

Minimal form factor: Ensures the module is compact enough to fit in various working environments.

Electrical Safety Requirements

The USB 3.0 optical module must conform to strict electrical safety standards to ensure the safety of users and patients:

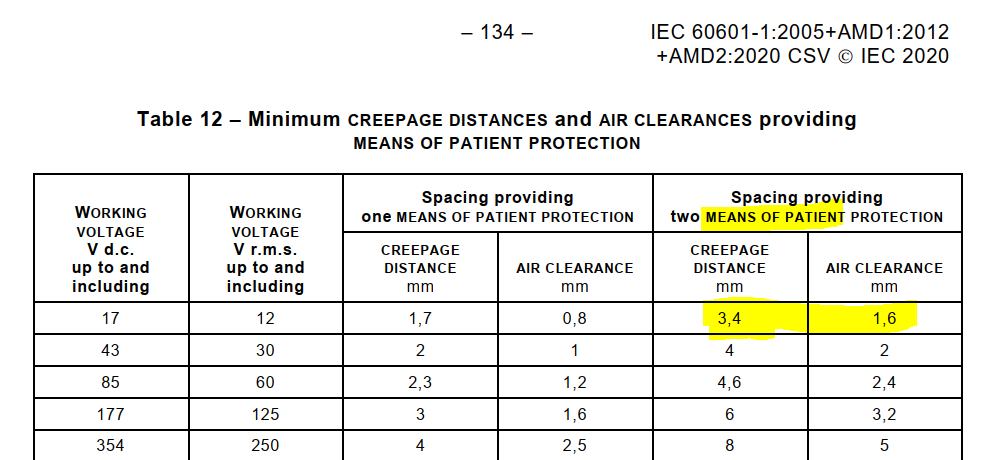

2MOPP: The USB 3.0 optical module provides 2MOPP, meeting the electrical safety requirements of IEC 60601-1 Ed 3.2.

Dielectric strength: The USB 3.0 optical module’s dielectric strength is 4000VRMS for 1 minute, ensuring electrical isolation.

Leakage input to output: <100 μA at 264VRMS 50-60Hz, ensuring current leakage is within safe limits.

Creepage distance/clearance: The cable’s creepage distance is 3.4mm, and the clearance is 1.6mm, meeting safety standards.

ESD protection: The USB 3.0 optical module has 15KV (air discharge) / 8KV (contact) ESD protection, ensuring prevention of electrostatic interference.

Optocoupler: The optocoupler conforms to IEC60747-5-5 standards.

Shielding: Electromagnetic shielding performance is pending to ensure electromagnetic compatibility.

Mechanical Requirements

The mechanical design of the USB 3.0 optical module is crucial for reliability and durability:

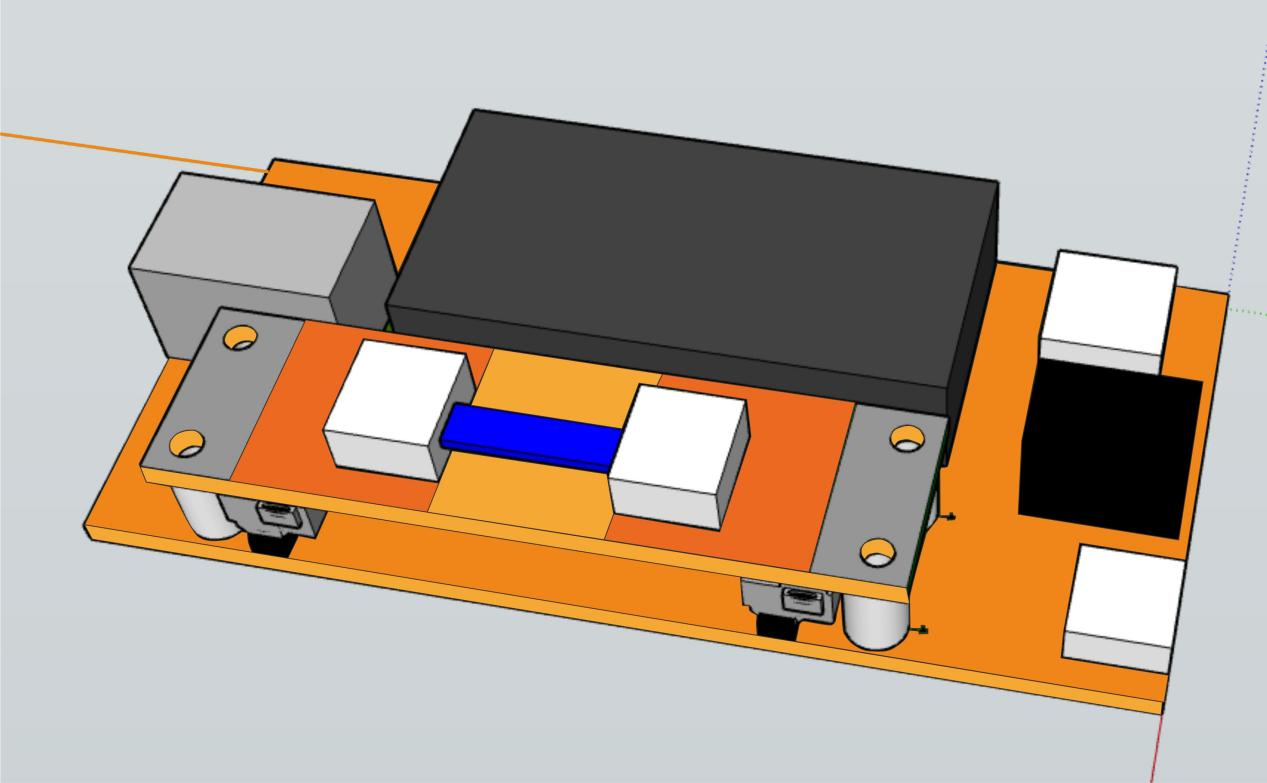

PCB Mounting: The USB 3.0 optical module is mounted on top of the interface box PCB via PCB mounting, ensuring a reliable connection.

Electrical Connection: The electrical connection is completed through two separate board-to-board connectors, with a requirement of at least 2mm PCB thickness to support PCB assembly tolerances.

Flammability Standard: Uses plastic parts and PCBs that comply with at least UL 94V-2 and UL94V-0 to ensure the flammability of materials meets requirements.

Environmental Requirements

The USB 3.0 optical module must operate reliably under various environmental conditions.

Operating Temperature: The USB 3.0 optical module should maintain full functionality at environmental temperatures up to 70℃, accommodating usage in different environmental conditions.

Impact Resistance: The USB 3.0 optical module undergoes ETSI EN 300 019-2-3 / IEC 60068-2-27 testing to ensure impact resistance meets requirements.

Reliability Requirements

The USB 3.0 optical module must have high reliability to ensure long-term use.

Lifespan: The USB 3.0 optical module has a lifespan of at least 5 years, with a working requirement of 3300 hours/lifespan.

Insertion Cycles: The USB 3.0 optical module’s connector is designed to withstand a minimum of 6500 insertion/removal operations.

Cable Cleaning (applicable only to option 2): The cable should be cleaned using a light detergent or 96% IPA to maintain cleanliness and reliability.

Standard Compliance

The USB 3.0 optical module complies with the standard for optoelectronic devices IEC60747-5-5: 2020. In terms of Electromagnetic Compatibility (EMC), the USB 3.0 optical module meets the requirements of EN 60601-1-2 Edition 4.1/ 2014+A1:2020, ensuring no electromagnetic interference is produced or affected by external disturbances.

Advantages of the Optical Module

High-Speed Data Transmission: Whether it’s the embedded optical converter module or the hybrid cable solution, the USB 3.0 optical module of the medical device manufacturers achieves USB 3.0 data transfer speeds of up to 5Gbps, ensuring that images from the oral scanner are transmitted in real-time to the laptop. Electrical Isolation: These modules provide reliable electrical isolation, ensuring a safe connection between medical devices and computers while meeting the electrical safety requirements of the IEC 60601-1 standard. Regulatory Compliance: The USB 3.0 optical modules of the medical device manufacturers strictly adhere to medical regulations and standards, providing a trustworthy solution for the medical industry.

Through collaboration with SmartAVLink, medical device manufacturers have successfully developed USB 3.0 optical modules, meeting the connectivity needs of oral scanning applications in the medical field. These modules offer high-speed data transmission, electrical isolation, and regulation-compliant connectivity solutions, providing healthcare professionals with better tools while ensuring patient safety and data reliability.

Challenges and Solutions

Despite the clear advantages of USB3 optical electrical isolation technology in many aspects, it still faces some challenges. Firstly, cost is a major barrier. High-performance optical isolation components are often expensive, which may limit their widespread adoption in cost-sensitive applications. Secondly, design complexity is another challenge, especially when integrating this technology into existing systems. To overcome these challenges, companies like Smartavlink are actively seeking innovative ways to reduce costs, for example, by optimizing design and manufacturing processes and using more economical materials. Additionally, working closely with customers to provide customized solutions for specific needs is an effective strategy to address design complexity.

Conclusion

As an advanced data transmission and security technology, USB3 optical electrical isolation technology has demonstrated its powerful potential in the collaboration between Smartavlink and medical device manufacturers. It not only improves data transmission speed and efficiency but also significantly enhances the safety and stability of systems. Despite facing challenges in cost and design complexity, these challenges are gradually being overcome through continuous technological innovation and collaboration. Looking to the future, USB3 optical electrical isolation technology will continue to play its unique role across various fields, becoming a key force in connecting and shaping future technologies.