Towline cables are more resistant to wear, durability, bending and even torsion resistance for ordinary cables.

Automation equipment manufacturers should not be too strange to high-flex cables, but many customers are not too clear when purchasing products, how to test the number of times the cable is bent, how many times can it be qualified?

Now that there is no standard for flexible and bend-resistant towline cables, the TUV Rheinland Robot Cable Test Standard is now a simple explanation of the test items and standards for highly flexible and bend-resistant towline cables.

Towline cables are more resistant to wear, durability, bending and even torsion resistance for ordinary cables. In order to ensure that the cable has data to ensure the function and quality of the cable, Industrial Camera needs to adopt the TUV Rheinland robot cable test standard, the towline bending test, and the double pulley.

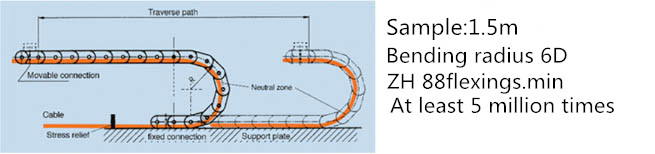

Towline bending test project:

This test is a must for the towline cable with a bend radius of 6D. The running speed is 88 times/min, the length of the towline cable is 1.5 meters, and the number of drag chains is at least 5 million times.

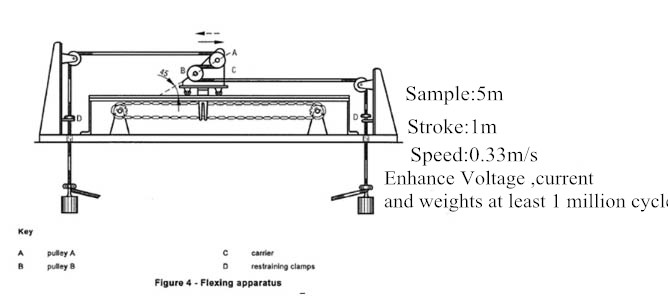

Flexure of double pulley

This test evaluates the cable to withstand tensile force in the radial direction, increasing voltage, current, weight, using sample 5m, running distance 3m, speed 0.33m / s at least 1 million times.

The above two are the two tests that must be tested for the towline cable. Only high-quality products can gain the trust of customers and ensure that the products are better.