Precautions for purchasing industrial cameras

How to choose industrial cameras in practical applications such as machine vision and industrial imaging?

1、Analog Camera & Digital Camera

The analog camera must have a digital capture card. The standard analog camera has a low resolution and the frame rate is fixed. This should be chosen according to actual needs. In addition, the analog camera collects an analog signal, which is converted into a digital signal by a digital capture card for transmission and storage. Analog signals can be distorted by electromagnetic interference from other equipment in the plant, such as motors or high voltage cables. As the noise level increases, the dynamic range of the analog camera (the ratio of the original signal to the noise) decreases. The dynamic range determines how much information can be transferred from the camera to the computer. Digital cameras collect digital signals that are immune to electrical noise. Therefore, digital cameras have a higher dynamic range and can transmit more accurate signals to computers.

2、The Resolution of Camera

The size of the camera resolution is chosen according to the needs of the system. The following is an application case analysis.

Application case: Assume that the surface scratch of an object is detected. The size of the object to be photographed is 10*8mm, and the required detection accuracy is 0.01mm. But the practical problem is that if a pixel corresponds to a defect, then such a system must be extremely unstable, because a random pixel can be mistaken for defects. So in order to improve the accuracy and stability of the system, the area of the defect is more than 3 to 4 pixels, so the camera we choose is also 1.3 million by 3 or more, that is, the minimum can not be less than 3 million pixels. Usually the camera with 3 million pixels is the best (I have seen Most people hold sub-pixels and say that they need to do a few sub-pixels, so they don’t need such a high-resolution camera. For example, if they do 0.1 pixels, it is a defect corresponding to 0.1 pixels. The size is calculated by the number of pixels. How do you tell the area of 0.1 pixels? These people use sub-pixels to fool people, often indicating that they have no common sense. ) In other words, we only used it for measurement purposes, then the sub-pixel algorithm, 1.3 megapixel camera can basically meet the needs, but sometimes because of the effect of edge sharpness, when extracting the edge, just shift a pixel, then the accuracy is greatly affected. Therefore, if we choose a 3 million camera, we can also allow the extracted edge to deviate by about 3 pixels, which is a good guarantee of measurement accuracy.

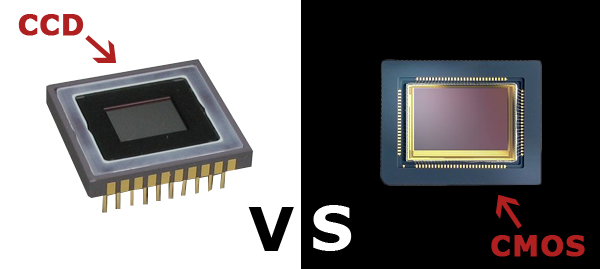

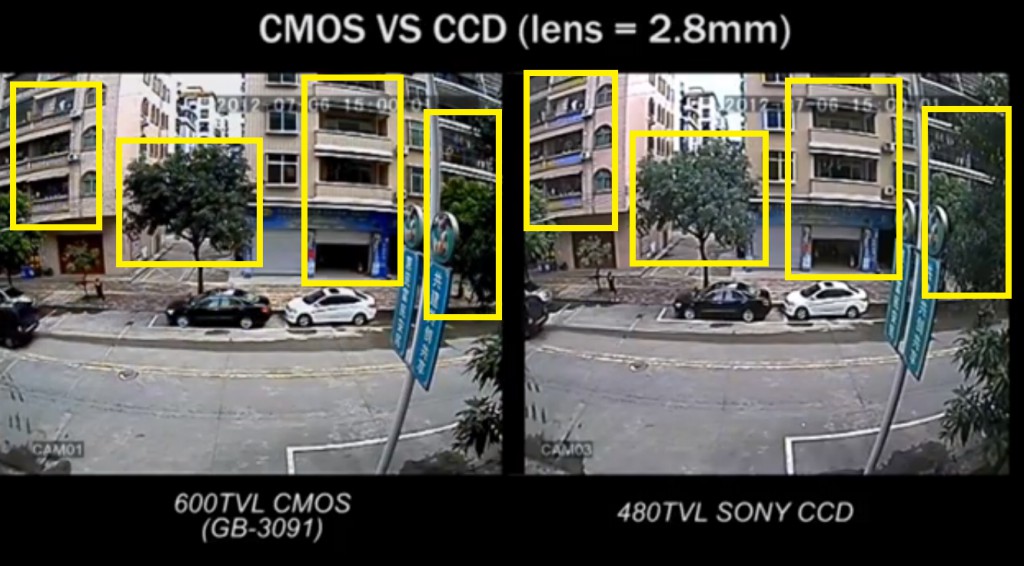

3、CCD & CMOS

If the object to be photographed is moving, and the object to be processed is also an object moving in real time, then of course, a camera with a CCD chip is most suitable. However, some manufacturers’ CMOS cameras can also be used as CCDs if they use frame exposure. Also, if the object moves at a very slow speed, the distance of the object movement is small within the exposure time range we set, and the pixel size is also within one or two pixels. Therefore, it is also suitable to select a CMOS camera. Because within the exposure time, the deviation of one or two pixels is not visible to the human eye (if it is not used for measurement), but the deviation of more than 2 pixels, the image taken by the object has a smear, so you can not choose CMOS camera.

4、Color & black and white

If we want to deal with the color of the image, then of course a color camera will be used, otherwise it is recommended that you use black and white, because the camera of the same resolution in black and white, the precision is higher than the color, especially when looking at the edge of the image, black and white will have better effects.

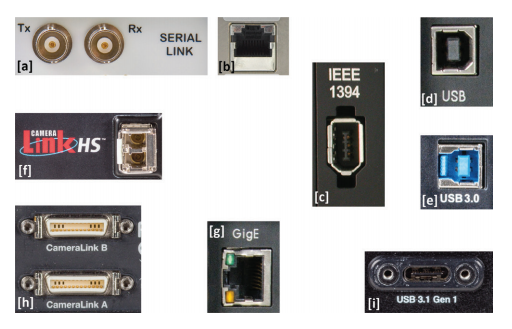

5、The interface of Transmission

Choose a USB, 1394, Camerlink, 100 Mbps/Gigabit network camera based on the distance, stability, and data size (bandwidth) of the transmission.

6、Frame rate

Depending on the speed to be detected, the frame rate of the selected camera must be greater than or equal to the detection speed. In the situation of equal to , the time you process the image must be fast, and must be completed within the exposure and transmission time of the camera.

7、Linear array & area array

With the circumstances of the detection accuracy is very high, the resolution of the area array camera does not meet the requirements, of course, the linear array camera is an inevitable choice.

8、CCD Target surface

The size of the target surface affects the length of the focal length of the lens. At the same viewing angle, the larger the target size, the longer the focal length. When selecting a camera, especially when the shooting angle is relatively strict, the size of the CCD target surface, the cooperation of the CCD and the lens will directly affect the angle of view and the sharpness of the image. Therefore, when selecting the CCD size, it should be selected together with the focal length and the angle of view of the lens. Generally speaking, the CCD target surface should be combined with the physical installation space to determine whether the working distance of the lens is within the installation space. And the size of the lens is required to be greater than or equal to the camera’s target size.

Smartavlink focuses on OE conversion technology, USB series active optical cable products used on machine vision, industrial camera etc.

If you have inquiry about these products, please contact us.